Luckily my Warn HS9500i has been very trusty since 1997 till present... that is until recently when I was testing all the equipment on the TJ for an upcoming trip. I was determined to figure out & troubleshoot why my winch was not working & fix or repair it myself. This would also help in taking the guess work of troubleshooting one on the trail.

I attempted to locate step by step documentation with no luck. I removed the winch off the Jeep and after an hour I figured out a few common test procedures. Afterwards I made a call to Warn about the big secret in hopes of getting a few pointers to make life a bit simpler & to confirm my findings in the event I was barking up the wrong tree.

I was fortunate to speak to one of the electrical engineers, we spent around 25 minutes on the phone talking electrical. He showed me a few tricks to make life a bit easier in dealing with a winch problem. It was determined that most models basically have the same troubleshooting techniques even though they might differ in model, motor, solenoids, etc. Once a few things were confirmed and clarified it was not really that hard to figure most of the mystery out.

The Main thing is to determine if it is a solenoid or motor problem.

1. Hook up your winch controller: Check the pins on the winch side of the male plug to see that there is 5 metal pins showing flush. A good percentage of the problems are pins that get pushed inside the plug. If you see any that are pushed inside, fix the problem by pushing them out again.

Check the female side of the plug of your controller... I've had & seen the inside connector move around not aligning properly on the inside notch. Make sure it is align on the notch and push all the way back until you hear a click sound.

2. Another simple but common problem is both the positive & negative connections at the battery become loose (this happened to me a few years back). A loose connection will cause the winch to click and not work. You don't want to completely disassemble your winch only to find out that all that was wrong was a loose connection at the battery.

3. Toggle remote controller to the "In" and "Out" side. If you hear clicking (on both ends), it is a possible sign that it is not a solenoid problem (but not necessarily) but a motor problem if you have determined that your battery connections are good. If the "In" or the "Out" does not click, it is a solenoid problem.

I personally will check to see if there is a motor problem if I hear clicking while cycling the controller "In" and "Out" before I continue to trouble shoot to see if there is a solenoid problem.

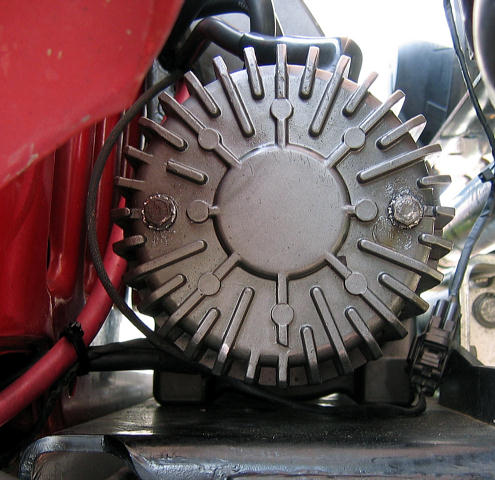

4. Checking for winch motor problem:

IMPORTANT: PLACE THE WINCH IN FREE SPOOL MODE.

A. Disconnect all connections located at the top of the winch motor housing, they are labeled A, F1, & F2 at each connection. Leave the ground wire connected to the bottom of the winch body motor connected to negative post of the vehicle battery. Disconnect the positive from the vehicle battery.

B. A set of jumper cables might make the next connections easier to do. Connect a jumper wire from connection A to F1, connect positive 12 volt from the battery to F2. If motor & roller turn, go to the next step, if not... something is wrong with the motor. Next connect a jumper wire from A to F2 & connect the positive from the battery to F1. The winch motor & roller should start turning the opposite way. If any of these fail, there is something wrong with the motor. It could either be a ground inside the motor housing, bad or dirty brush, bad or dirty contacts. Hopefully this is the case instead of the motor being toast which means buying a new one. If all is working properly, proceed to troubleshoot the solenoids in step 5.

C. Take the motor apart by removing the two long bolts at the end of the motor housing. After you remove the cover & brush plate, the motor should turn freely, look inside at the condition of all the parts which will determine by common sense if you need a new motor or not. If nothing is fused together and it looks pretty clean, use fine sand paper to clean the main brass body of motor, contact plates on the wall housing, brass brush contact, & brass brushes. Take note on how it all goes together. Sand paper all washer, bolts & contacts they belong to.

Re assemble all except for the last part which will be the outer casing with the two longer bolts. Look at the longer bolts, they come with a flat & lock washer.

Take the flat washer and move it to the inside of the cover as you slide the bolt through the housing cover. Take a new steel flat washer and install on the outside of the housing along with the lock washer. This procedure will help make a better ground for the outer housing cover to the brush plate... this is the most common grounding problem of a winch.

After all is put back together repeat procedure "4B". If the motor & roller start to turn there is a good possibility that you have fixed your problem & your winch solenoids are fine. If the motor does not turn... you need a new motor.

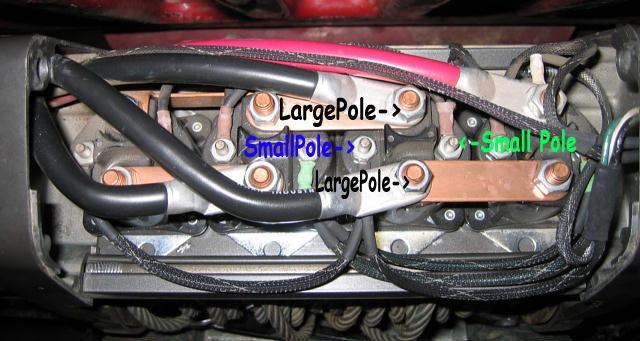

5. Troubleshooting Solenoids: Total of 4, look at the bridged connections. It will usually be wired (from left to right as you are looking at the front of the winch) 1 & 3, (usually will pull in), 2 & 4 (usually will roll out). You will need a meter that can measure DC & Ohms (continuity).

If you plan to remove all solenoids from the winch and test all four of them individually, REMOVE THE WINCH (RED) POSITIVE CONNECTION AT THE VEHICLE'S BATTERY FOR SAFETY.

Workings of a Solenoid:

A. You will have two larger poles & two smaller connector poles. The two larger ones are the ones that open & close the bridge connection. They are normally open. Test this with an Ohm meter by taking a reading on the two larger poles. There should be no continuity, meaning an open connection. If you get a reading of a close (continuity or bridge) connection without power (remote not engaged or solenoids out of the winch) than replace the solenoid. Test all solenoids in this manner for an open connection.

B. Next you will test each solenoid to see if they can make a closed (or bridge) connection. I will discuss two different scenarios, the first... solenoids are out of the winch and in your hand. Second... while they are all connected to the winch & all wiring connected.

First Scenario: Hook up a 12 volt connection one of the smaller pole on the solenoid. With a jumper wire, connect the smaller 12 volt pole to a larger side pole. Be sure to ground the body or the opposite smaller side pole. Take an Ohm reading between the two larger poles after all these connections are made, you should have a bridge (or continuity) connection between the two larger poles. If you don't, the solenoid is bad.

Second Scenario: Since all the solenoids are connected to the winch, connect your remote controller & make sure that both the positive and negative cables are properly connected to you vehicle's battery. Have someone toggle the controller either in, or out & hold. Take your ohm meter and check for continuity. There should only be two of them bridging because you are only working one side off the controller. It will either be 1 & 3 or 2 & 4. Toggle the controller to the other side and check again. If any of the solenoids do not bridge on this procedure, than you have located your bad solenoid. Remove & Replace the bad one, no need to disconnect and take the rest of them out.

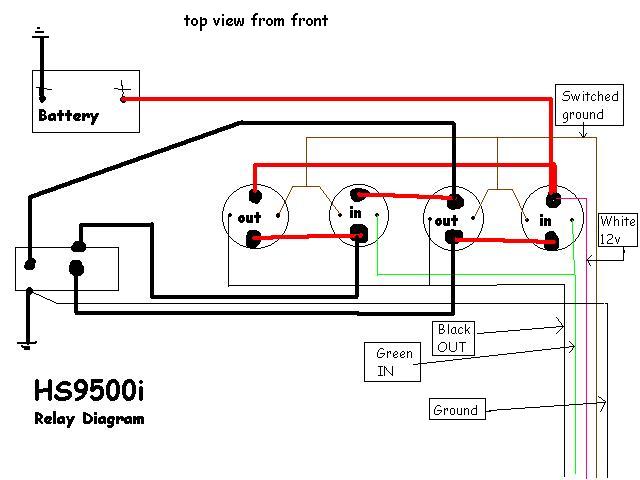

Below is a picture of a basic wiring diagram:

Points to remember:

1. Battery Connections Loose.

2. Remote Control Pins on the Male side pushed in, female side not aligned.

3. Determine if it's a motor or solenoid problem.

4. Test motor, if it does not work, take it apart & clean. Check for ground connection.

5. Determine which solenoid. (two ways).

If you can basically remember all these simple procedures, you can avoid yourself a lot of grief, time and unnecessary expense of someone having to trouble shoot the problem & possibly replacing a motor when it might not be needed.

Help

Help